Cub Cadet FAQ's

Hydro Trunion Repair

Info stolen from IHCUBCADET.COM

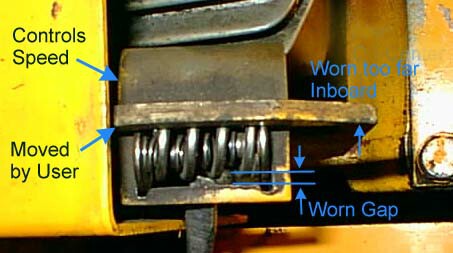

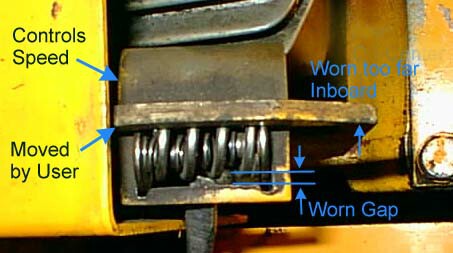

The centering springs in the trunion arm/cam plate joint

allow a small amount of

movement or cushion in the speed control linkage. This is designed into it to

prevent the hydro from bucking you off the seat every time you move the speed

control lever....just like a shock absorber dampens a suspension.

The hydro WANTS to self accelerate....that's why FRICTION is built into the

speed control lever, to hold it in place. If you loosen the friction adjustment

and barely bump the hydro lever it will automatically move to wide open...it's

the nature of the beast.

The centering spring is designed to only compress during speed changes, at all

other times it should be in the neutral position, holding the hydro at constant

speed. If the springs become weak, or the slot becomes elongated (effectivly

decreasing the spring force) they will not maintain their "N" compression when

the tractor is moving fwd/rev. Instead, they will compress and allow the tractor

to "free wheel"/self accelerate downhill, or "bog down"/self decelerate up

hill.....just like a worn out shock, it no longer dampens then holds, it "sort

of"

dampens then bottoms out. When you compress the weak springs due to

increased/decreased load you change the effective length of the speed control

linkage and the tractor speed changes accordingly.

Hope that's not confusing, but that's what is happening.

Those same centering springs are also the reason why it's hard to hook 2 hydro

linkages together to make a 4wd...different spring rates/hydro

performance/individual

pump differences/etc make the hydros fight each other. Kelly Birkey (owner of

the 1450

4wd and 1450 payloader) and a few of the forum regulars had a conversation about

that at RPRU. made for some interesting discussions.

First you have to recognize the problem

Then you get down to fixing it.

There have been several ways but I prefer the methods shown

here.

Once you have everything removed and cleaned up, and your parts assembled,

your ready to begin.

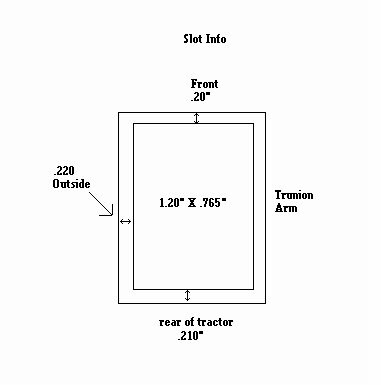

The keystock method is used by many and works very well.

Get some 5/32"x1" keystock and braze or weld it to where

you have these

dimensions for the springs to rest in.

You will end up with something that looks like this or close to it.

As long as your doing it, you just as well replace the springs, They do weaken with age.

Put everything back together and it should look like this,

Once all that is done and everything is back in

place, go to

Operation

Neutral Adjust and finish the job up.